Sewage

and Litter

ABOUT US

Gasification Consultancy Limited (GCL) is a UK based company which has its own 'Biomass and Waste Gasification Technology' patent. Using this patented technology, it carries out projects that set a precedent in the field of waste disposal and the production of energy from waste on a global scale.

SERVICES

GCL stands out in the biomass and waste technologies sector with the following expertise;

- Biomass waste gasification process information

- Practical experience of designing and installing biomass waste gasification plants

- Gasification plant patents

- High Voltage Plasma Gas Cleaning System

- Consultancy, design, commissioning, operation, and licensing services to Biomass and Waste Gasification,

Combined Heat and Power Plants in the international waste-to-energy market.

GCL GASIFICATION

PROCESS

GCL Plant Flowchart and Income Stream

-

Low capital and operating cost

-

Excellent R.O.I.

-

Sustainable CHP* Generation

-

Responsive to market needs

-

Safe 24/7 unmanned operation

-

Low profile and low impact

-

Intensive and miniaturized

FEEDSTOCKS

GCL gasification technology can work with multiple feedstocks simultaneously.1.2 ton of waste generates 1 MWe electricity plus 3 MWt of heat

ECONOMIC BENEFITS

- The GCL process turns inexpensive feedstocks, biomass, and waste into valuable commodities such as electricity, substitute syngas, fuels, chemicals, and fertilisers. Wasta management plants can reduce operating costs by gasifying MSW instead of using costly natural gas.

- Gasification plants have much lower operating costs than conventional processes as they are more efficient, require less back-end pollution control equipment, are fully automated and need fewer on-site staff.

- The GCL process offers wide fuel flexibility between solid, gas and liquid feedstocks. This provides greater freedom to adjust to feedstock price and availability.

- Biochar, the principal by-product of gasification, is a rich source of carbon. It is readily marketable as a fertiliser or for water purification.

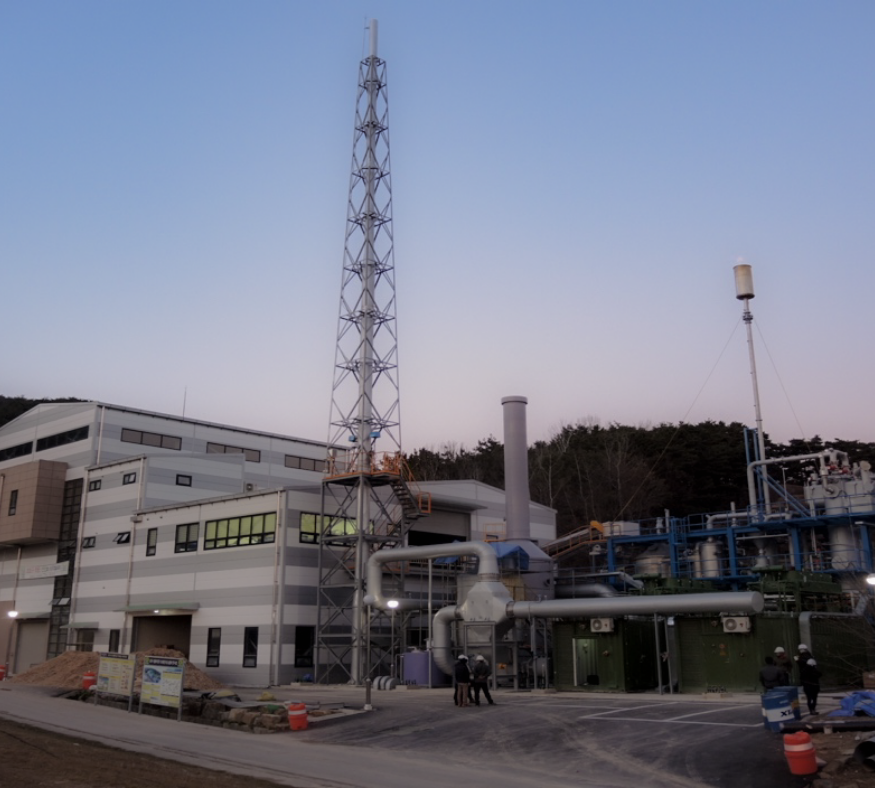

PROJECTS

EVR Gasification Plant

Comissioned: 2021

Site location: Türkiye

Feedstock type: RDF

Gasifier Capacity: 360 tons/day

Power Generation: 12 MWh

BGB Gasification Plant

Comissioned: 2020

Site location: Türkiye

Feedstock type: Chicken Manure

Gasifier Capacity: 72 tons/day

Power Generation: 2.5 MWh

HAYAT MDF Plant

Comissioned: 2016

Site location: Gebze, Türkiye

Feedstock type: MDF

Gasifier Capacity: 60 tons/day

Power Generation: 2 MWh