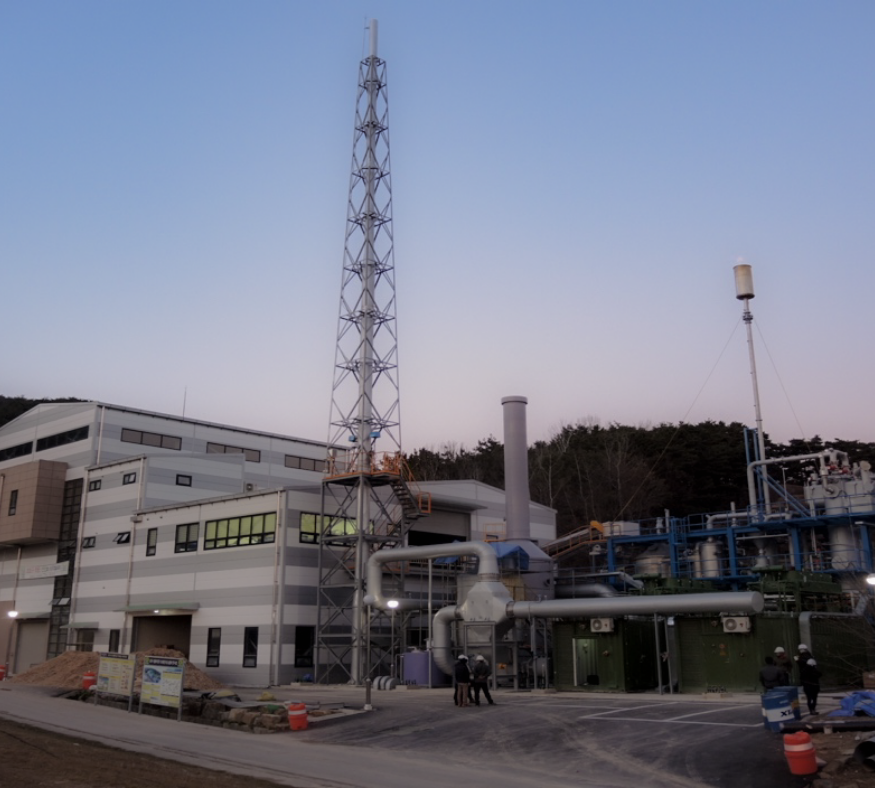

GCL GASIFICATION TECHNOLOGY

Gasification process is at the forefront of the clean renewable energy revolution. It produces highly profitable syngas that can be used to power the generation of electricity, heat and cooling, from household, industrial, and biomass waste.

GCL can convert materials normally considered waste into energy and valuable commodities. The waste that we discard from our homes and businesses every day contains energy. This includes non-recyclable plastics, construction debris, old tires, household rubbish and sewage. This energy can be converted into electricity and thermal generation for heating and cooling.

ADVANCED TECHNOLOGY

GCL technology is the cleanest, and the most flexible and reliable way of utilising waste. It can convert low-value residuals into high-value commodities, such as chemicals and fertilizers, substitute natural gas, transportation fuels, electric power, steam, and hydrogen.

- GCL provides the least-cost alternative for capturing CO2 when generating power.

- GCL offers the opportunity to use readily available, renewable, domestic resources. Local material can replace costly, imported oil and natural gas.

- GCL provides increased domestic investment and jobs in industries that have been in decline because of high energy costs.

- GCL offers a new path to energy development and consumption consistent with robust environmental stewardship.

OPPORTUNITY

Over four billion tons of waste are produced each year, but only 2% of its energy potential is currently used.

This creates a huge opportunity to turn this waste into clean, renewable energy. With the GCL gasification process for recovering energy from unwanted waste, we can achieve:

- Reduced disposal of industrial, rural, and domestic waste in landfill sites

- Dramatic reductions in the carbon footprint of power generation from waste

- Ongoing compliance with global environmental legislation

- Decreased dependency on fossil fuels

- Access to government and international incentives

- Increased reliance on locally sustainable and renewable energy

ECONOMIC BENEFITS

- The GCL process turns inexpensive feedstocks, biomass, and waste into valuable commodities such as electricity, substitute syngas, fuels, chemicals, and fertilisers. Waste management plants can reduce operating costs by gasifying MSW instead of using costly natural gas.

- Gasification plants have much lower operating costs than conventional processes as they are more efficient, require less back-end pollution control equipment, are fully automated and need fewer on-site staff.

- The GCL process offers wide fuel flexibility between solid, gas and liquid feedstocks. This provides greater freedom to adjust to feedstock price and availability.

- Biochar, the principal by-product of gasification, is a rich source of carbon. It is readily marketable as a fertiliser or for water purification.

- Using commercially available technology, GCL power plants can achieve engine efficiency of 35-40 percent. Technology improvements will boost this efficiency to significantly higher levels.

GCL GASIFICATION

PROCESS

GCL Plant Flowchart and Income Stream

-

Low capital and operating cost

-

Excellent R.O.I.

-

Sustainable CHP* Generation

-

Responsive to market needs

-

Safe 24/7 unmanned operation

-

Low profile and low impact

-

Intensive and miniaturized